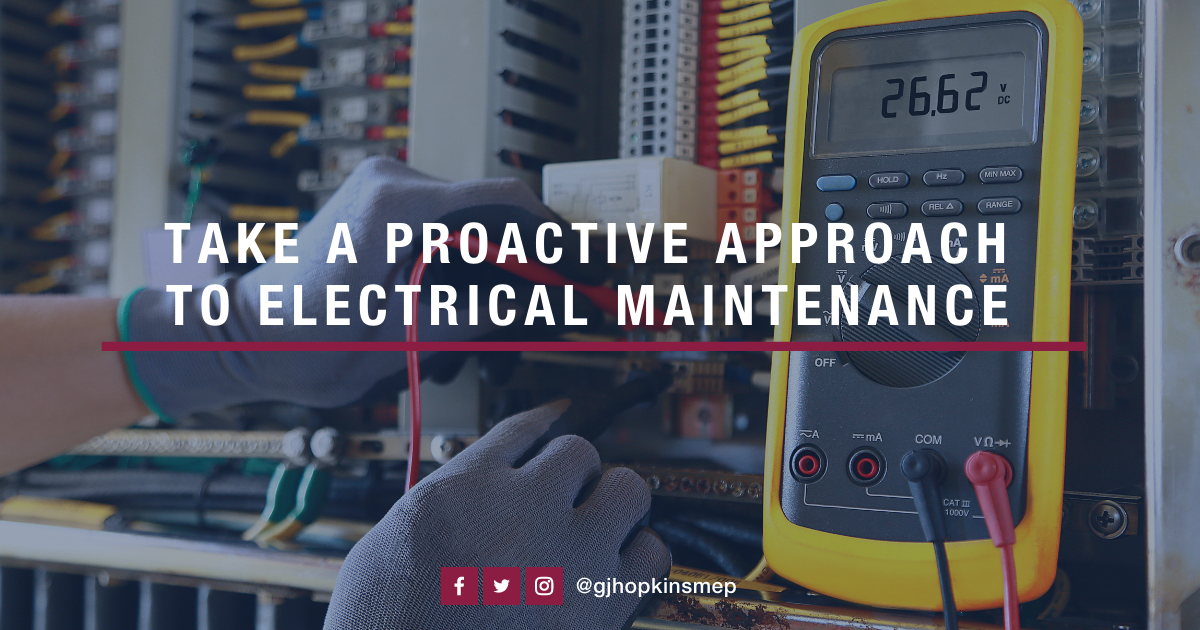

Your electrical equipment can break down for several reasons, including mechanical failure, environmental conditions, and human error. All three can result in unanticipated downtime, which can be costly. To avoid service disruptions, we suggest that our commercial and industrial clients focus on predictive maintenance.

With a regular predictive maintenance schedule, our electricians can detect and correct problems before they shut down equipment or cause a safety incident. In fact, studies show an effective electrical maintenance program can reduce the risk of outages by as much as 66 percent*.

How do we perform electrical predictive maintenance?

Our electrical tests and inspections are non-invasive, do not require an outage, and occur during normal operating conditions. Some of the tools and techniques used in predictive maintenance programs include:

1. Infrared thermography

With thermal imaging equipment, electrical systems can be inspected while under load and energized. This process will help our electricians spot thermal hotspots that would otherwise be invisible.

2. Partial discharge (PD) testing

A partial discharge is a localized electrical discharge in an insulation system that does not completely bridge the electrodes. It is an early indicator of a degrading insulation system, which could lead to very costly repairs or an electrical breakdown.

3. Circuit monitor analysis

Circuit monitors record voltage, current, and power data. They can help our electricians understand where and when dangerous and destructive sags and swells occur.

These predictive maintenance services provide the data our electricians need to anticipate and plan future maintenance as well as future system replacements or upgrades, saving you time and money.

To see what a predictive maintenance schedule would look like for your commercial or industrial facility, contact our Service Department at (540) 982-1873 or gjhservice@gjhopkins.com.